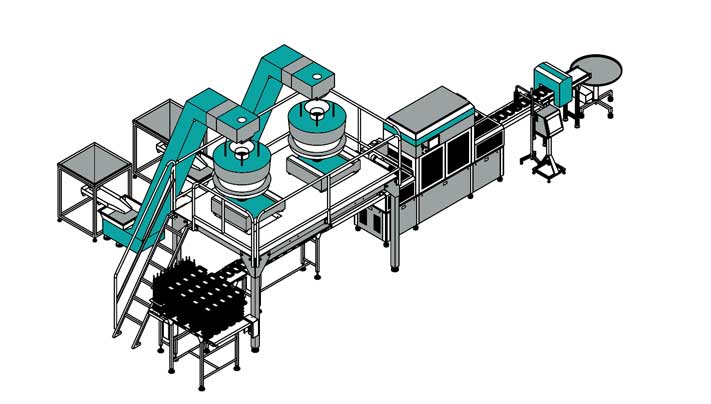

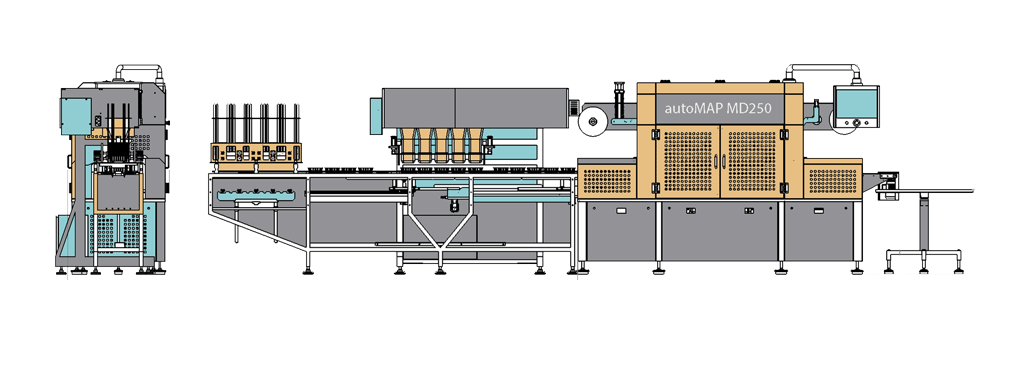

Fully Automatic Robotic Arm MAP Tray Sealing Machine

If you need high capacity MAP packaging automation, this is what you search for. autoMAP-MD250 series full automatic MAP tray sealer line gives you a hand more than a standard Mapping machine. On basis, there is not so much difference between autoMAP100 to autoMAP200 models. autoMAP-MD250 is suitable for high level production. The line may contains tray dispanser, autofilling unit, scaling, mapping, labeling, barcoding, collecting etc. units depends on your demands.

.png)

The machine name dedicated to our valued friend Mr. Muharrem Demir's honoured memory. The most professional solution for MAP Modified Atmosphere Packaging line includes vacuum and protective food gas options.

| autoMAP-MD250 |

|

Stainless-steel body and hygienically designed conveyor belts and moving parts allow for cleaning and maintenance without any hassle. It also suitable for using single and multiple trays.

Accomplish with excellence by Functional Control System

By means of touch-screen panel, every step of the packaging process can be controlled easily. The automation unit with PLC control circuits, monitors and controls processing line provides immediate alerts on possible faults, misuse, and equipment malfunctions, thus protects the systems. Multiple program memory makes it easy to switch to different package types. All procedures can be adjusted according to various trays and films sizes.

Gradual vacuum application ZERO2XYGEN permits all gasses to be removed from the package. Liquid foods, sauces, dressings and hot-filled products can be hermetically sealed with ease. In this way, all the oxygen in the package and in the product is taken out. After the desired atmosphere prepared for the package, the upper film is sealed over preformed food tray. Now the package is closed tightly. The corelation inside and outside of the package is interrupted.

The use of natural gases together with proper packaging materials and machines help to maintain the quality of the food and prolong their shelf life. The MAP gas mixtures usually consist of the gases already present in the air that we breathe but in different compositions: carbon dioxide (CO2), nitrogen (N2) and oxygen (O2). The gas mixture is added before the trays are sealed.

| USAGE OF autoMAP-MD250 |

|

Our autoMAP-MD250 serie mapping machines provides quick service and cleaning facilities by easy-removable side covers . All frames and intermediate elements were manufactured with ISI304 stainless steel.

We build the autoMAP-MD250 unit with using polished construction materal for safe and hygiene in VDE-CE standards . All machine series have EMERGENCY STOP function.

Mould can change very quickly and easily. Automatic tray dispanser, automatic product scaling and filling unit, labeling and barcoding units, product collectors and boxing units can be added.

All machine can command via over very useful PLC touchscreen. LCD Graphic Display with touchscreen is very easy to use. Multilingual programmed control panel can turn to the desired direction in VDU norms. Adjustable up to 99 different process programs. The minimum and maximum temperature values can be monitored simultaneously on the touchscreen. The unit’s working order and possible errors, error logs are displayed on the control display. All the settings and features of the machine functions can be controlled from the touchscreen. If necessary, the work settings can be avoided by locking for the potential user faults. Counting products, hours of operation, cycles, production process, errors, functions reports can show in any time on the control panel.

Our MD250 series machines have international certificates of conformity. We are certified for ISO22000 Food Production and ISO13485 Medical Equipment Production.

The MD250 series has been designed for long uninterrupted productions, and is offered with service and separe parts with our APACK warranty both our national and international customers.

| autoMAP-MD250 Technical Details | |

|---|---|

| POWER | 200-400V, 50-60Hz, 3/N/PE |

| POWER CONSUMPTION | min 4.0 – max 8.0 kW |

| VACUUM PUMP | 205-305 m³/hour |

| COMPRESSED AIR | 6 Bar Consistent and Dry Air |

| COMPRESSSED AIR CAPACITY | 80 Nl/cycle |

| PRESERVATIVE GAS PRESSURE | 2- 6 Bar |

| FILM WIDTH | 320 mm. |

| FILM ROLL INTERNAL DIA. | 76 mm. |

| FILM ROLL EXTERNAL DIA. | 300 mm. |

| CAPASITY | 8-10 cycle/min (Vacuum and Gas) 12-15 cycle/min (Only Sealing) |

| OPTIONAL | Liquid / Dust Filter |

| CONTROL CIRCUIT | Omron PLC (Programmable Logic Control) |

| CONTROL PANEL | Touch Screen HMI (Human Machine Interface) |

| LOADING AREA | 1.5-3.0 m |

| WIDTH | 940 mm |

| LENGTH | Machine 2900 / With Conveyors: up to 5100 mm |

| HEIGHT | 2040 mm. |

| WEIGHT | Approx. 1500 Kg. |