Fully Automatic Tray Sealer

We manufacture packaging machines for all kinds of production styles, production capacities and production choices. We are constantly improve and innovate our machines with the needs of our customers.

We have also redesigned our fully automatic packaging machine model for our customers with limited production areas and limited investment budget. We produced small and economical models.

Our EcoSEAL 100Mini model, which we have developed, incorporates all the structural features of our fully automatic machines. It provides automation, does not burden your budget, and provides great convenience in terms of placement in the production area.

TheEcoSEAL 100Mini Packaging Machine is suitable for attaching all kinds of accessories, like all fully automatic machine models. Automatic tray dispenser, automatic weighing and filling units, UV Disinfection, Metal Detector, Printer, Barcode Applicator etc. All packaging line accessories are automatically operated within the EcoSEAL 100Mini without any problems.

It is the most suitable solution for your food/medical packaging that does not require vacuum and gas.

| EcoSEAL 100Mini |

| HAS CERTIFICATES OF CONFORMITY TO INTERNATIONAL INDUSTRIAL STANDARDS |

| CAN FIT IN SMALL PRODUCTION AREAS. |

| IT HAS A FULLY AUTOMATIC OPERATING SYSTEM |

| IT IS VERY SIMPLE TO USE. |

| THE FEATURE OF REMOTE ACCESS TO THE MACHINE OVER THE INTERNET IS AVAILABLE. |

| COMPATIBLE WITH ALL KINDS OF PACKAGING ACCESSORIES. (PRINTER, WEIGHER, ETC.) |

| PRINTED / UNPRINTED FILM CAN BE USED. |

| PRINTED/UNPRINTED TRAYS CAN BE USED. |

| THE MOLD CAN BE CHANGEABLE. |

| MADE WITH HIGH QUALITY WORKMANSHIP. |

| EASY TO MAINTAIN AND CLEAN. |

| CAN BE REGULATED FOR ANY PRODUCT. |

| SUITABLE FOR FOOD and MEDICAL PACKAGING. |

The production lines prepared with our EcoSEAL series machines are designed completely according to the needs of the customer. We produce completely customized solutions to suit your other production machines and size of your production area.

EcoSEAL series are packaging lines that can meet all your packaging needs with fully automatic systems. Operation starts from tray placing, covers all stages such as filling, weighing, sorting, sealing, labeling, collecting and stacking the product.

The body of our machines is completely made of AISI 304 stainless steel. Molds are processed from 5000 and 7000 series aluminum on our own CNC machines. Moving belts and moving elements are made of hygienic material. Mechanical, electrical, electronic and pneumatic parts are selected from the highest quality brands. The machine is very easy to use, maintain and clean.

It is suitable for the use of single or multi-compartment trays.

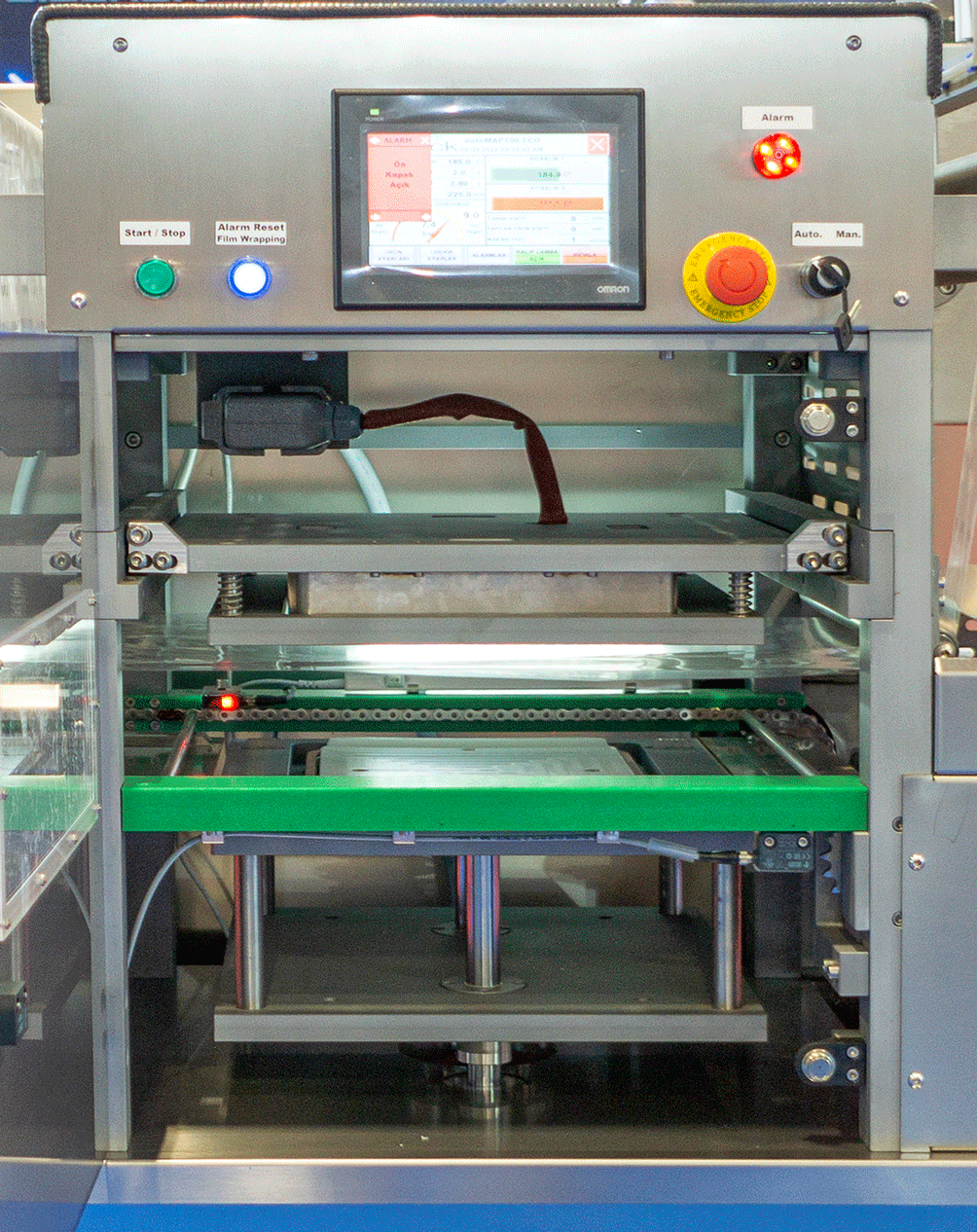

Thanks to its colored touch screen, every step of the packaging process can be easily controlled. With a large number of PLC control circuits, all stages of production and possible error messages are instantly displayed on the screen. All processes can be adjusted in accordance with all kinds of trays and films. With 99 program memories, it is possible to easily switch to different production models. Mold changing, film rolls changing applications are much simplified. In this way, all kinds of interventions can be easily performed by the company staff.

The PLC unit, which performs all kinds of monitoring and control of the production line, immediately warns about possible errors, misuse and installation malfunctions and protects the system.

Our EcoSEAL series machines are designed considering the working conditions in your country and are manufactured by APACK. Our EcoSEAL series machines are designed for long-term uninterrupted production.

.png)

The MAP technique, which requires Vacuum and Gas, is not applied to EcoSEAL machines. In our machine, fully automatic tray sealing is performed by thermal-transfer method. For this reason, it is preferred in food products that do not require shelf life. Daily patisserie and bakery products, portioned snacks, takeaways, dried foods, ready meals, salads, delicatessen items are suitable for EcoSEAL

It is especially suitable for the products prepared on the shelves of the big markets for daily consumption. Sealed products will maintain their freshness all day long in the cold chain (+4oC).

| USAGE |

| SOLID - LIQUID READY MEAL (Soup, sauces, tomato paste, appetizers etc.) (Daily Consumption) |

| DELI (Cheese, appetizers, snacks, brine, etc.) (Daily Consumption) |

| PEELED AND CLEANED FOOD (Daily Consumption) |

| SALAD - VEGETABLES - FRUIT (Daily Consumption) |

| GRANULES AND POWDER MATERIAL |

| FROZEN PRODUCTS (Daily Consumption) |

| MEAT AND MEAT PRODUCTS (Daily Consumption) |

| NUTS - DRY FOOD |

| SEA FOOD (Daily Consumption) |

| PASTRY - PASTRY - DESSERT (Daily Consumption) |

| MEDICAL MATERIAL |

| MILITARY LOGISTICS |

If you choose suitable tray and top film for your food with the right parameters, your product will reach your end user in the right conditions. APACK will be happy to guide you in this regard.

We have service and spare parts for EcoSEAL 100Mini.

Our EcoSEAL series machines have CE certificate. It is under protection with the utility model certificate numbered 2010/07255 and 2010/05885. Our company has ISO9001 / ISO22000 / ISO13485 certificates of conformity.

Our company provides support for the supply of all kinds of trays and multilayered films that you will use in your packaging.

| EcoSEAL 100Mini Technical Details | |

|---|---|

| POWER | 200-400V, 50-60Hz, 3/N/PE |

| POWER CONSUMPTION | minimum 4.0 – maximum 8.0 kW |

| PRESSURED AIR | 6 Bar Homogeneus Dry Air, 25Nl/cycle |

| CONTROL SYSTEM | 7" Omron PLC (Programmable Logic Control) HMI (Human Machine Interface) Colored Touch Screen |

| OPERATION | Fully Automatic Chain Drive with Pneumatic System |

| FILM WIDTH(Max) | 420 mm. |

| FILM REEL INNER DIAMETER(Max) | 76 mm. |

| FILM REEL OUTER DIAMETER(Max) | 300 mm. |

| CAPACITY | 8-10 cycle/min |

| LOADING AREA | 1.5-3.0 mt |

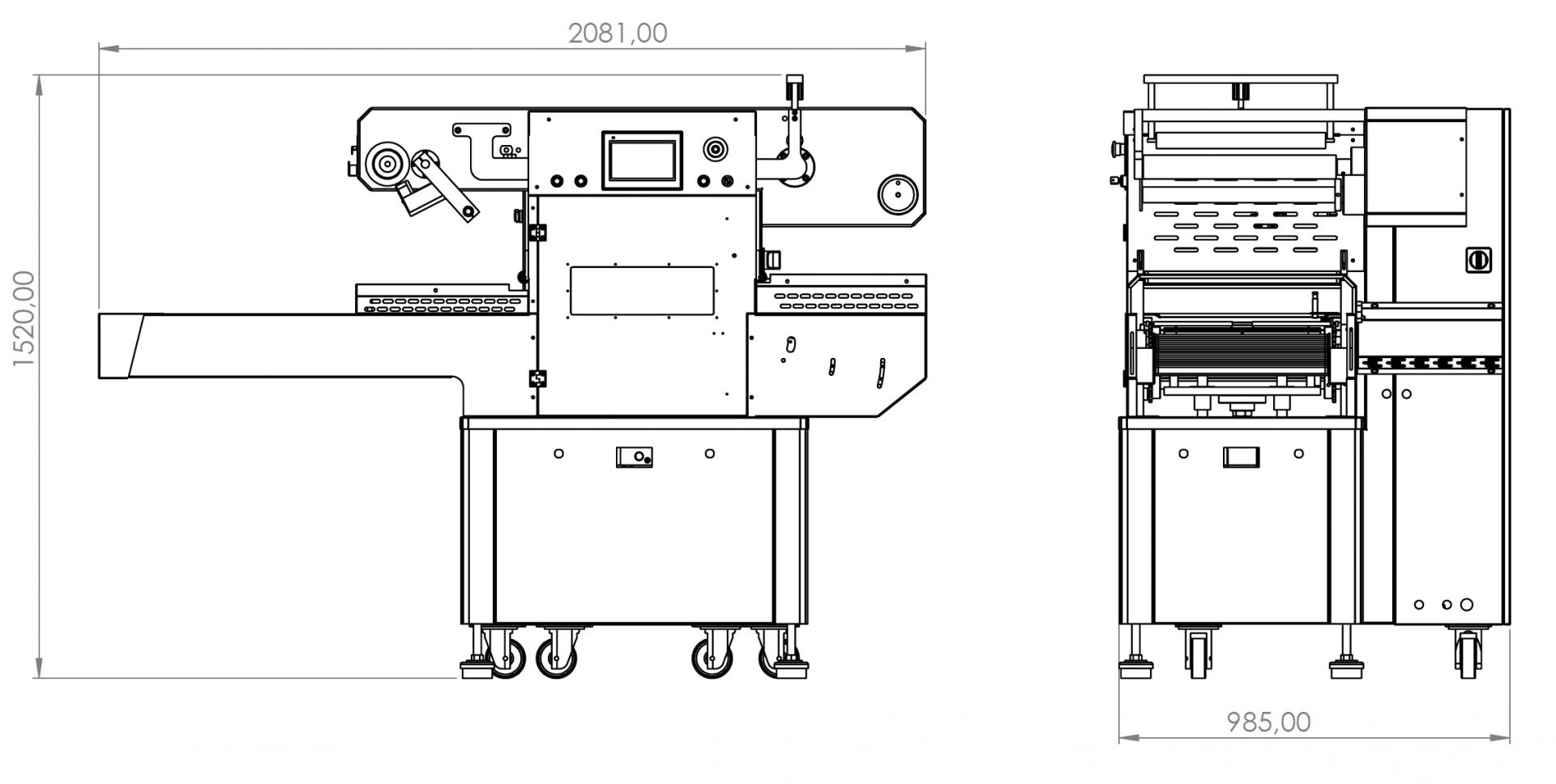

| DIMENSIONS | 985/2081/1520mm. |

| WEIGHT | Approx 500 Kg. (Only Machine) |