Semi Automatic Changable Tool Tray Sealer

The semiautomatic tray sealing machine TableTOP20 is an electrically heated, motor drive tray sealing and cutting machine, is used to seal trays with various type packaging films.

TableTOP20 series machines are semiautomatic type tray sealer which has compact design, build with stainless steel to meet the market that wants healthy, tasteful and convenient packaged in a hygienic, high-quality way. The machine have skillful craftsmanship at a great value for money, which are suitable for testing market demands, low level production, fast packaging requirements, supermarkets, small kitchens and shops. This kind of machines are the very first step through fully automation.

| TableTOP20 |

|

.webp)

TableTOP20 series semiautomatic type tray sealing machines is applicable to fresh-keeping packaging of all types of boxed nutrition as fresh, cooked food, such as cool fresh meat, cooked meat products, rice, noodle, cheese, soy products, fast food, food-to-go, which can be hot, chilled or frozeen, pastry, aquatic products, dried food, poultry and other boxed foods or any kind of boxed material. It is perfect for following take-out sales. Take-away, casual dinning, meals-on-wheels, street food and cooked & chill.

TableTOP20 series sealing machines allows you easy and fast replacement of tray tools.

TableTOP20 series sealing machines allows you friendly and simple in operation for user. Machine needs only one operator.

TableTOP20 has an tool change option. You may use different kind of toolset for your different products.

TableTOP20 Semi-Automatic Tray Sealing Machine allows the use of single or multi-compartment trays at different depths from 10 mm to 100 mm. Only one staff is sufficient for its use. To ensure ease of use, a stainless steel work table is prepared for machine dimensions.

TableTOP20 tray termosealing unit works with asynchronous electric motor and has the ability to make faster, better quality and more powerful seal on other desktop machines. The sealing process is controlled by electronic systems.

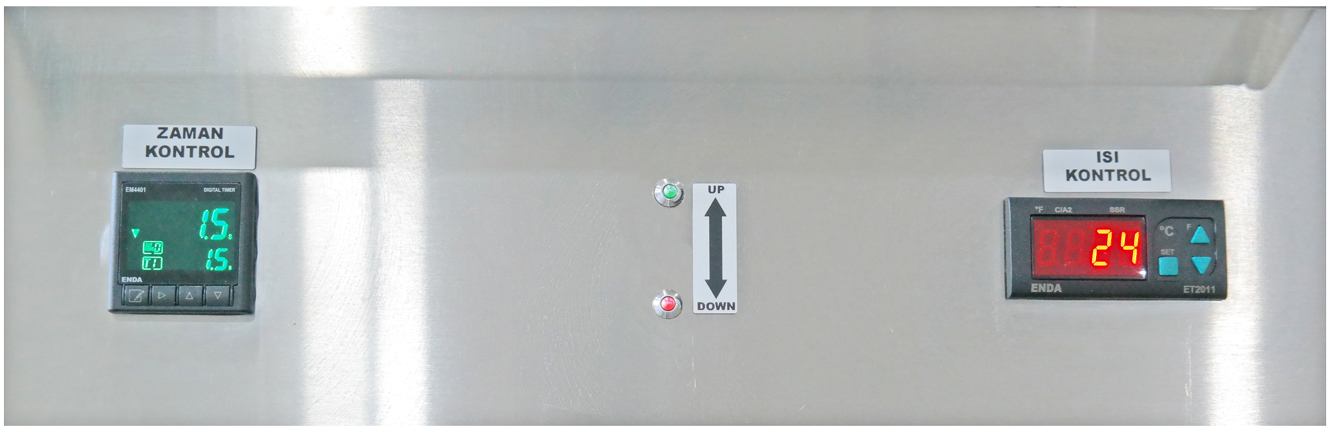

TableTOP20 series sealing machine has digital heat control system and sealing timer. In this way, the quality of the termosealing almost access to fully automatic machines.

Stainless-steel body and hygienically designed conveyor belts and moving parts allow for cleaning and maintenance without any hassle. It also suitable for using single and multiple trays.

APACK can customize TableTOP20 machines and tray tool dimension which is suitable for your production.

| USAGE of TableTOP20 |

|

| tableTOP20 Technical Details | |

|---|---|

| POWER | 1/N/PE 200-220 V 50-60 HZ |

| POWER CONSUMPTION | 2.0 kW maximum |

| CAPACITY | 6-10 işlem/Dk |

| PRESSURED AIR | Not Need |

| CONTROL PANELS | Digital Heat Controller and Digital Sealing Timer |

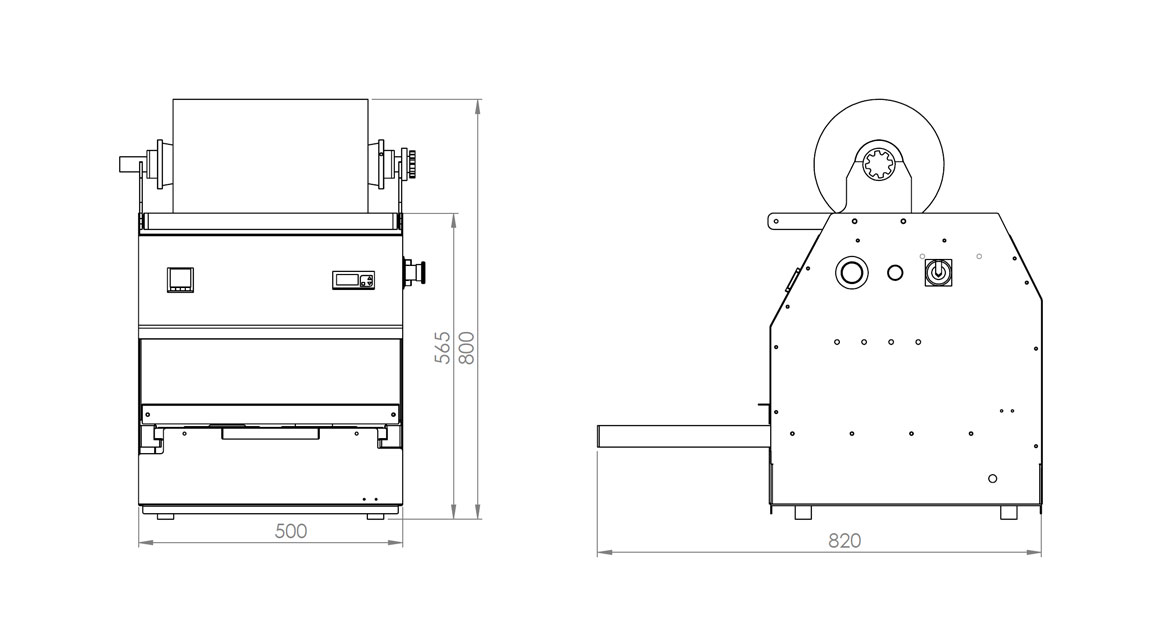

| DIMENSIONS (mm) | 500x820x800 |

| FILM WIDTH | Maksimum 380mm. |

| FILM REEL DIAMETER | 76mm. |

| WEIGHT | 60 Kg. |

| OPERATION | SEAL and CUT |

| OPTIONAL | Stainless Steel Trolley |