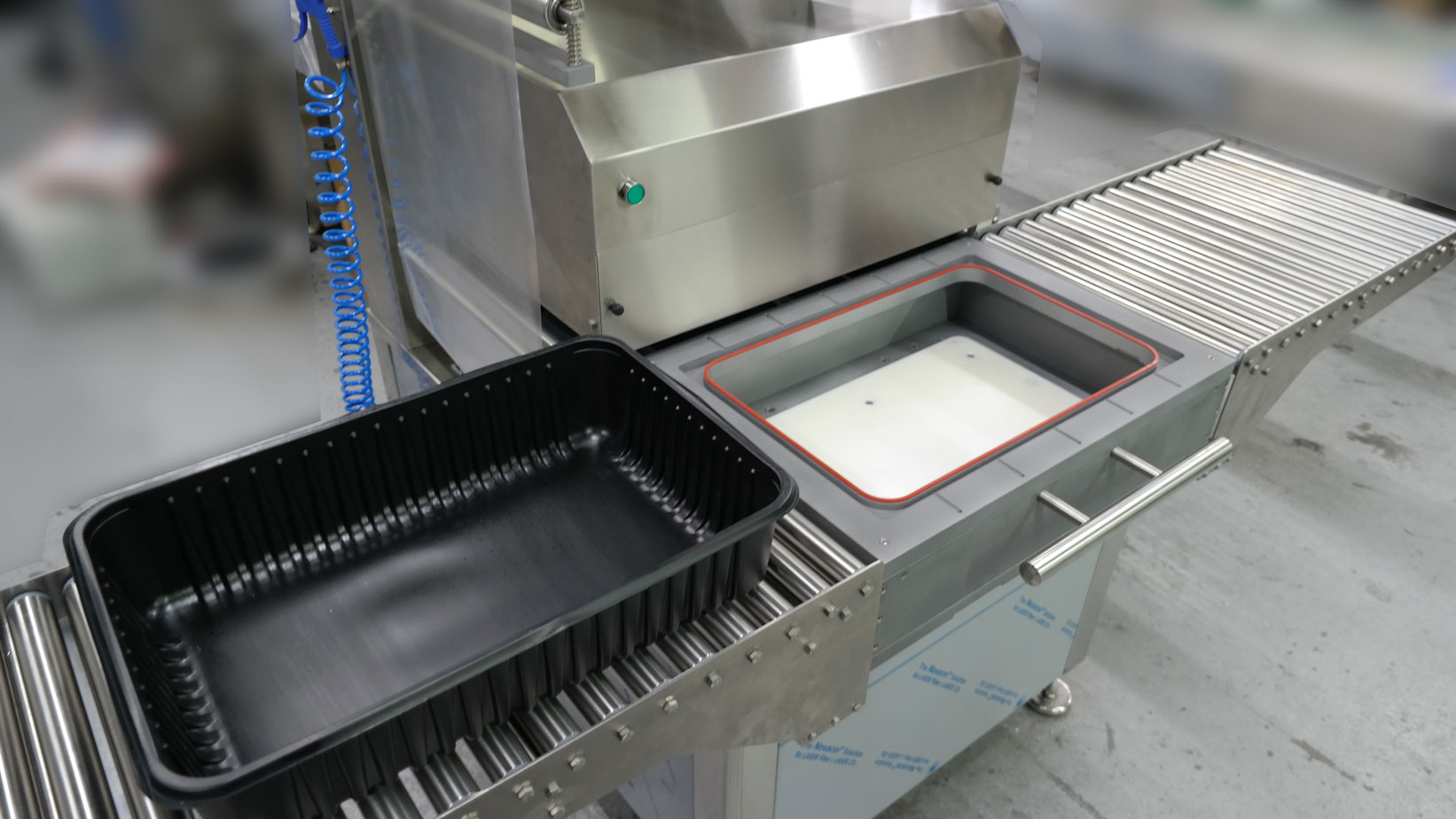

Semi Automatic BULK (Big Size) MAP Packaging Machine

The MAP25E-XL is designed specifically for your non-standard large and heavy MAP packaging needs. The basic functions are like the MAP25 series, but a number of different engineering applications have been made for large and heavy packagings.

On free-turn carriage bearings, heavy material is shifted into the welding pool. Thanks to the pneumatic lift, the heavy plates are easily lowered into the pool and lifted up. The welding drawer can easily be pushed into the welding pool and retracted without the need for much effort, with the help of linear guideways without gaps. The plate, which is packaged in MAP, is taken out of the machine again via free-turn bearings.

Another important feature of MAP25E-XL is that the welding pool is washable. It is ideal for products polluting the environment with spillage, odor or oil.

MAP25E-XL is designed for heavy duty conditions and manufactured by APACK. The AISI 304 Stainless Steel body is extremely robust and the machine’s movement does not affect its settings. It is very easy to maintain and clean. Fits easily in any production environment.

7 ”Omron touch screen PLC controls every step of the packaging process. With PLC control circuit, all stages of production and possible error messages are displayed on the screen. Gas and Air pressure information can be viewed on the screen. All kinds of trays and film types can be adjusted to suit the process. With 99 program memory, you can easily switch to different production models.

MAP25E-XL molds are manufactured from monoblock aluminum with anodized coating. Welding plates are Teflon coated. The product is sealed between the heating plate. Bottom welding plate, top mold, knives, heaters and PT100 are a whole.

With its special software, gradual vacuum process can be applied easily. This way, all oxygen in the package and product is removed. Liquid foods, sauces, even products that need to be packaged hot can be hermetically packed.

After the atmosphere in the package is formed as desired, the top film is closed by sealing to the edges of the plate and the inside of the package is disconnected from the outside world.

.jpg)

We can extend the shelf life of your product up to two years with the right technical information and the choice of suitable plates and top film for your food. APACK will be happy to guide you in this matter.

Our MAP25E-XL machines have international certificates of conformity. We are certified for ISO22000 Food Production and ISO13485 Medical Equipment Production.

The MAP25E-XL has been designed for long uninterrupted productions, and is offered with service and separe parts with our APACK warranty both our national and international customers.

All types of films to be used in MAP25E-XL packaging are offered by APACK.

.jpg)

| MAP25E-XL TECHNICAL SPECIFICATIONS | |

|---|---|

| POWER | 400V, 50-60Hz, 3/N/PE |

| POWER CONSUMPTION | 6kW maximum |

| VACUUM PUMP | 105m³/h |

| COMPRESSED AIR | 45Nl/cycle, 6 bar Dry Air |

| GAS | 2‐8 bar |

| CONTROL SYSTEM | OMRON HMI PLC TOUCHSCREEN |

| DIMENSIONS (mm) | 920x1280x1990 |

| WEIGHT (WITH VACUUM PUMP) | 650 Kg. |

| FILM WIDTH | 480 mm. |

| FILM REEL DIAMETER | 76 mm. |

| CAPACITY | 4-6 cycle/min (Vacuum and Gas) 8-10 cycle/min (Only Sealing) |

| OPERATION | Semi automatic with drawer. Elevated Pool |