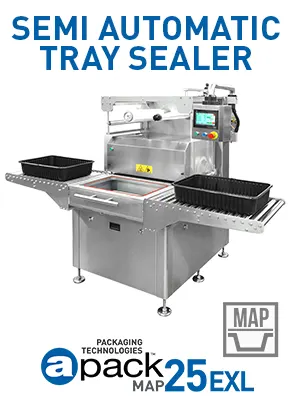

The MAP25 series stands out as the most proficient and dependable among its counterparts. It boasts exceptional durability and does not tend to malfunction, thus preventing operational issues. Moreover, this unit is designed to fit compact production spaces and can be effortlessly cleaned, serviced, and operated. Notably, all models in this series are suitable for packaging food and medical products.

Designed and engineered for small to medium-sized manufacturers, the MAP25 series is a remarkable innovation. It has an impressive production capacity of up to 5000 packages per shift and can handle solid and liquid products. The unit supports various package shapes, including square, triangular, round, rectangular, and single or multi-compartment formats. Moreover, the products can be filled at hot or cold temperatures, and the packaging method has no adverse effects on the product.

MAP25 series can apply MAP-SKIN-CARDBOARD packaging methods. There are many different models according to their intended use. You can choose from these models according to your production purpose, market, product and budget.

|

|

|

|

|

|

|

| MAP25 is the basic model of this series. All models have basic features. Its design and technology are much improved. The stainless steel body is extremely robust and the machine's settings are not disturbed in displacements. The body is made of AISI304 stainless steel, the molds are made of 5000-7000 series aluminum, high resistance and long life casting sealing pool, suitable for industrial systems. Electrical, electronic and pneumatic materials of the world's most valuable brands are used. |

If you require increased production capacity but lack the budget to upgrade to a fully automatic system, our Map25DS Double Station model is ideal. Incorporating two stations on a single body, the MAP25DS enhances production capacity without incurring high costs. Our DS model features all the capabilities of the MAP25, and it accommodates both plastic and laminated paper trays. Additionally, the unit supports using multi-layered printed/non-printed top film or laminated paper lids.

|

The standard MAP25 structure and mold dimensions have expanded to accommodate non-standard large packages. The unit's dimensions can be customized to suit your specific packaging requirements. Additionally, a free roller inlet and outlet conveyor can be integrated into the MAP25E model when needed while retaining all the features of the MAP25 unit. |

This unit features various engineering modifications explicitly designed for large and heavy packaging requirements while retaining the basic functionalities of the MAP25 series. The unit is particularly suitable for packaging products prone to spilling, emitting odors, containing oil, or polluting the packaging environment such as fish. To facilitate easy cleaning, the drawer pool is designed to be washable. The sealing pool is equipped with a lift to facilitate the processing of heavy packages. |

APACK has gained a great deal of experience over time, mainly in food packaging. Believing that food packaging machines should also have high health standards, we have paid a lot of attention to this issue in the design of our machines. Most of the MAP25 models are also suitable for medical packaging. The EXL model has elevator and slide die systems and is preferred for packaging sensitive medical material. |

Skin packaging methods on plastic tray or paper are new trends in the packaging industry. Although the techniques are similar, they differ based on the packaging material used. Despite their higher cost, these methods offer an effective shelf presentation and are particularly appealing to the new generation. These two methods have been increasingly employed in recent years to showcase the product's shape precisely on store shelves |

In the another type of the SKIN technology is uses flat, borderless laminated paper plates instead of plastic trays, named CARDBOARD.

The cardboard can be printed with a desired graphic design, which can be visually appealing to consumers. This type of packaging can be displayed on shelves or hung up. It is often used for portioned products. MAP25 series machines are capable of packaging SKIN technology in both TRAY and CARDBOARD. |

| AREAS OF USAGE |

- CENTRAL KITCHEN

- CATERING

- SOLID - LIQUID CONVENIENCE FOOD (Soups, sauces, paste, side dishes, etc.)

- DELI (Cheese, appetizers, side dishes, brine, etc.)

- PEELED AND CLEANED FOOD

- SALADS - VEGETABLES - FRUITS

- GRANULE AND POWDER

- FROZEN FOOD PRODUCTS

- FRESH AND PROCESSED MEATS

- DRIED NUTS - DRIED FOOD

- SEA FOOD

- BAKERY PRODUCTS - DESSERT

- MEDICAL PRODUCTS

- MILITARY LOGISTICS

|

|