Semi-Automatic MAP Modified Atmosphere Skin Tray Sealing Machine

In the 1970s, developed a method of Skin Packaging, is a technology that coating with a protective material like a second skin on the product. The shape of the product prepared in the same manner as the blister or carded packaging with plastic covers methods tried in foods but the desired results were not obtained. Because connection with the external environment of the product could not exactly stop. These methods are still widely used on non-food products. On the store shelves, you can find in this manner packaged products like pencils, scissors, a wide rande of spare parts and tools.

The most important factor in the packaging of food products is interrupt the connection to the external environment with the product. In this way, contamination will be slowed down and extended the shelf life of the product. With the methods called MAP (Modified Atmosphere Packaging) or CAP (Controlled Atmosphere Packaging) when closing the tray which in it the product has been placed, the air between the cover and the product completely taken out of while doing vacuum, instead of air, is filled with the gas that will slow down the deterioration, decay and mould of the products.

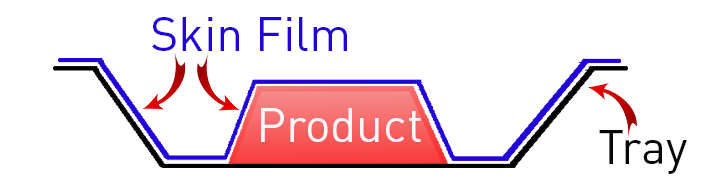

MAP25SP (Skin Pack) This type of model innovated for skin packaging. MAP25 have developed according to the needs of the industry.One of the modern packaging methods that can be performed in Skin Packaging. In this technology, top film cover the product as it’s shape like vacuum packaging without deformation of product. We can cover from 10mm to 35 mm height.

In Skin packaging method, the air is completely drained from the tray which the product is placed in, the upper is closed on the exact shape of the product to accommodate various laminated flexible film techniques. Thus, connection of the product with the external environment is completely cut off. The product is covered with as a second skin. No bubbles and completely airtight.

In today's technologies, according to the other production methods, the skin process is a little bit slower. However, significantly extends the shelf life. Certainly, trays and lid films used in the SKIN method has different characteristics. Produced with different technologies and layered. The cost of packaging per product compared to other methods is a bit more of, however, this results worth the investment.

SKIN packaging machine that is capable of technology is different from others. Even if the basic working principle is similar, on the skin packaging , firstly the top flexible film is termo-processed than applied and sealed over the product.

Either portioned or bulk SKIN packaged products are quite attractive on the Market Shelves. The skin packs are also suitable for produce with protruding parts such as bones. The end user is able to directly see the color and freshness of the product. Transparent films effects more fresh, crisp and appetizing on customer feelings. Through the SKIN technology, the product shape is never deformed, the product juice is never flow-out the package, the product is never slumpdown because of suspended or slanted shelves.

SKIN technology is extends the shelf life considerably more. The product is not correlation with the atmosphere, never loose color, never drain juices. Molding or contamination risks are significantly decreased.

SKIN packaging method is an environmental technology. Waste materials diminished. SKIN techology does not need any additives or polluting gas in packaging.

Especially in fast urbanizing regions in the emerging markets, especially in packaged products, the consumption of meat and meat products is rapidly increasing. SKIN packaging to be developed a long time ago but the markets just reach to cost efficiency for skin process. According to a recent survey packaging market volume will surpass 10 billion US dollars in 2020 increasing usage of skin it looks like.

However the product should need some processes just before an optimal skin packaging. You may fell into a distress experience if you try a fat and juicy cheese block in skin packaging. While packaging the meat with internal juicy and undrained blood, you may experience the same problem when packaging. No problem with solid and hard materials in this method. But soft and hydrated materials may needs additional processes. For right solutions in skin packaging, the machine manufacturer and the producer should be in a close cooperation. The packaging process adjustments are different for each product. Must be determined by experimenting with them.

The most economic solution for MAP Modified Atmosphere Packaging machine includes vacuum and protective food gas options.

| MAP25SKINPack |

|

Apack, follows closely the development of packaging in the world according to the emerging trends, production technologies and uses the strategy having application rapidly. APACK engineers was doing the work for a long time that to adopt the skin techonology to the machines. On food skin packaging machines in the world that can usually large, heavy and wide-area machines. The amount of production area and energy used is the factors that increase the cost. Therefore APACK engineers worked on smaller machines being able to do skin on. When SKIN packaging process reach cost efficiency that market requires, APACK launch their skin machines to the market. The first demand came from abroad. MAP25SKIN machine is developed for SKIN and sent to Europe and our technicians performed the installation and start process by reaching machine via internet from Istanbul. MAP25SKIN developed for our client that is producing meat and meat products have a significant share in the European market.

MAP25 has own Zero2 Oxygene software. With this software, MAP25 take all Oxygen progressively out from the package.

If you want to be a game maker in the world market, the question of “production cost” that you must move to the bottom of the list. Any investors asks “how much dos it cost” or “ what will be our activity per product” in first meetings in Europe. They are asking about is it environmental, contains hazardous waste, fits health and hygiene-related standards, what do you offer as new and different, what are the features of your machine etc.

Our MAP25 series machines have international certificates of conformity. We are certified for ISO22000 Food Production and ISO13485 Medical Equipment Production.

The MAP25 series has been designed for long uninterrupted productions, and is offered with service and separe parts with our APACK warranty both our national and international customers.

| USAGE OF MAP25 |

|

APACK supplies a wide range of solutions for practically various requirements. Depending on the product, you have the choice of many different types of pack as far as the atmosphere is concerned.

Longer shelf life thanks to MAP Packaging. Harmless inert gases – naturally present in the air that surrounds us – are fed into the pack after the evacuation operation and guarantee that the product has an extended shelf life and stays fresh longer. MAP Packs from APACK make sure no pressure is exerted on the product, so that it can be presented particularly attractively. Soft, porous and cut products rest loosely in the pack and maintain their color and taste too. Exactly the way they should !

APACK not only offers the very best food manufacturing, processing and packaging machinery & functional packaging material but also the 'Total Processing Packaging' service & support that is needed for customers to get the most out of them.

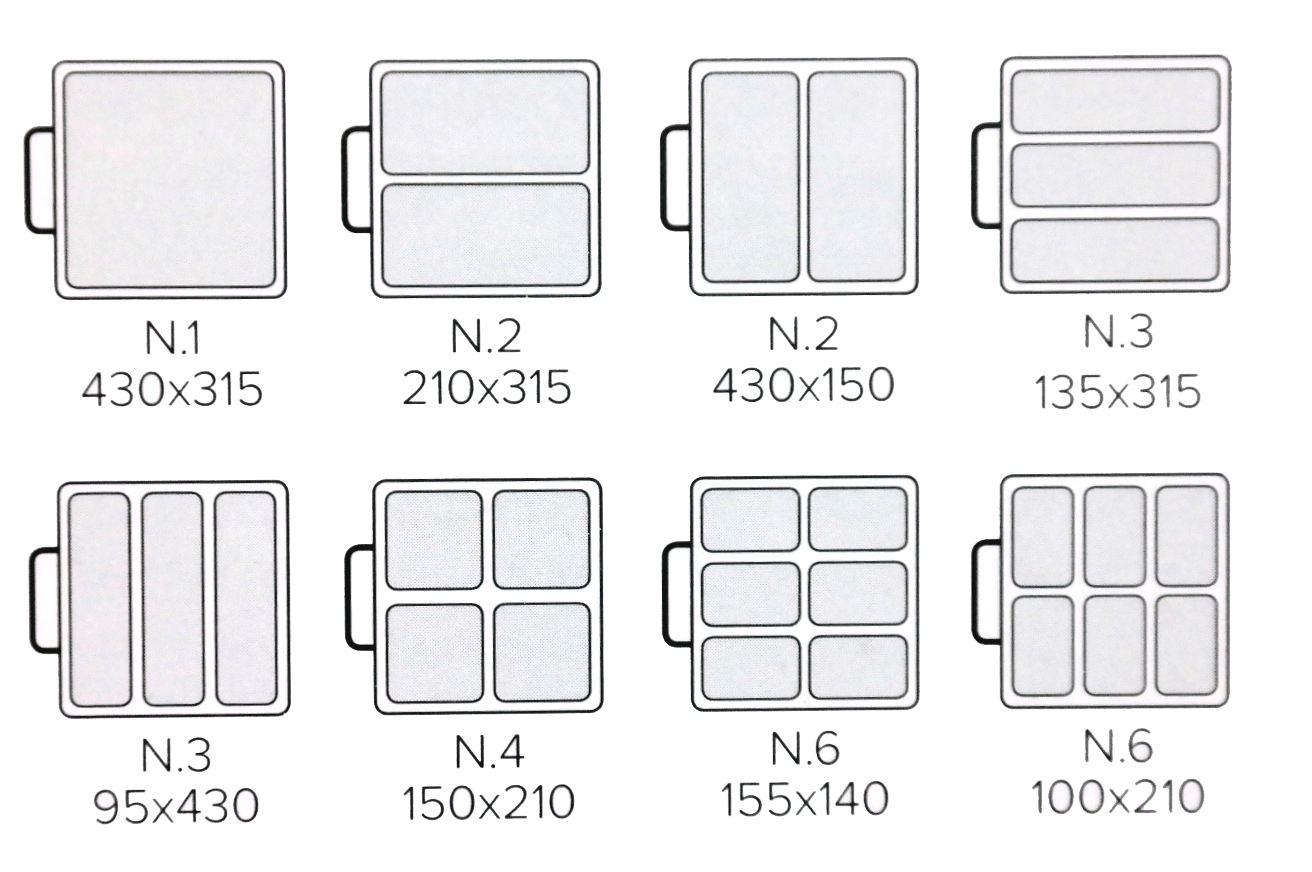

MAP25 STANDARD TOOL SET

| MAP25 SKIN TECHNICAL DETAILS | |

|---|---|

| POWER | 400V, 50-60Hz, 3/N/PE |

| POWER CONSUMPTION | 6kW maximum |

| VACUUM PUMP | 60m³/h |

| AIR PRESSURE CONSUMPTION | 8Nl/cycle, 6 bar Dry Air |

| GAS PRESSURE | 2‐6 bar |

| CONTROL SYSTEM | 7" Omron HMI PLC Touch Screen |

| OVERALL DIMENSIONS | 800x1250x1770 mm |

| WEIGHT (with vacuum pump) | 350 kg. |

| FILM WIDTH | 530 mm maximum |

| FILM ROLL DIAMETER | 76 mm maximum |

| PRODUCTION CAPACITY | 3-5 cycle/min |

| OPERATION | Semi automatic with drawer |